HW Open Source 6.5 Digital Voltage Meter (Part1: Schematic and working principle)

HW

Open Source 6.5 Digital Voltage Meter (Part1: Schematic and working principle)

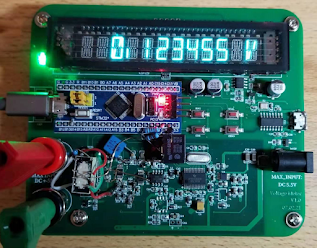

This is an open HW project, the target is

to build up a low cost high precise voltage meter with 6.5 digital resolution,

and ±50V input range. It has the capability to controlled by the upper level

control system and has a VFD display that can make it work independently.

This series of articles will be divided

into at least 3 parts:

Part1: Schematic and working principle

introduction.

Part2: HW Debugging and bug fix.

Part3: Calibration and performance test.

Part4: Temperature coefficient compensation

(not sure whether it works or not)

DIY Disclaimer

In this DIY project you may need to

use high voltage, electric soldering iron, etc. unfamiliarity with the tools

and process can be dangerous. This project should be viewed as entertainment

only. The author will not be held responsible for any injury due to the misuse

or misunderstanding of this DIY project. It’s purely “at your own risk”. If you

are at all uncomfortable or inexperienced working on projects yourself

(especially projects involving dangerous tools), please reconsider doing it by yourself.

It is very possible on any DIY to damage your property, create a hazardous

condition, or harm or even kill yourself or others. I am not at all

responsible for the actions you take after you have read this article.

DIY Background:

I bought 2 ADS1256 modules planned for my LCR

meter project, before I got all the material for my LCR meter project, I got several

VFD displays occasionally, then I put these 2 things together and found it

works quite well, you can see the prototype here:

https://aduecho.blogspot.com/2021/03/build-low-cost-65-digital-voltage-meter.html

This acritical will focus on the PCB version, which named Version 1.0.

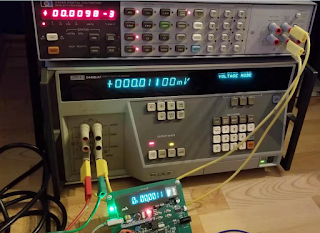

Base Range test result:

After some HW bug fixed, here are some pictures for the base range(±2.2V) testing, for the detail it will be descripted in Part B and Part C.

Schematic introduction:

1.1 ADC part

The core part is ADS1256, it’s a Very Low Noise, 24-Bit

Analog-to-Digital Converter.

Can provide up to 23 Bits Noise-Free Resolution. It integrates

a 1-64x low noise PGA, which helps for low level voltage measurement.

The whole system power by 5V, in order to accept true

bipolar voltage input we need to set the VCM to 2.5v, then the span at ADC

input port is ±2.5V, considering we need to give some space to the input amplifier,

thus the max linearity input range for ADC is ±2.2V(referring VCM).

The ADS1256 has an internal 2x amplifier for the reference,

in order to use the full range of the ADC, we need to set the Vref to 1.25V.

The input channel 2&3 are connected to VREF directly,

used for ADC gain performance testing. And channel 4&5 short circuit, for

ADC noise evaluation.

1.2 Voltage Reference

Considering cost and performance, it’s not easy to find a suitable

1.25v voltage reference for ADS1256. We need to find a low noise and low drift

reference to match with ADS1256’s performance. And the minimal input voltage

for the reference IC should be less than 5V, finally chose REF5025, here it’s

the key parameter for this IC, and seems VSSOP has a better performance compare

to SOIC-8 package, so here chose the VSSOP package, it’s a bit difficult for

hand soldering.

Resistor R1 & R2 working as voltage divider,

the resistor using here should have the same or similar temperature coefficient,

in order to reduce the temperature’s influence.

And U5 OPA350 used to buffer the 1.25V, and

it can drive huge capacitor, provide the peak current which is needed when

ADS1256 running at high ODR mode. But the weakness point is OPA350’s 1/f noise

is too high, which is not mentioned in the datasheet. It seems there is no

better choice, since the evaluation board for ADS1256 from TI is also using

OPA350 as buffer, maybe it's a compromise.

1.3 Analog input circuit and self-calibration circuit

J1 and J2 are the

input terminals. J2 connect to the VCM directly. J1 connected to the DVM_IN+ via

a reed relay. The reed relay used to switch the analog frontend to self-calibration

circuit and input terminal. The purpose of using reed relays here is to reduce

the EMF voltage, but during debugging it turned out using reed relay (HE721C0500)

here is totally wrong.

The DVM+ signal can be

routing to RNG_L or RNG_H via a low leakage SPDT analog switch U6.

R9/R10/L4/C19/C20 forms

a low pass filter for the low range, with a BW 100Hz. This filter refers to HP34401A’s

low range filter.

For the low range the

voltage divider is not used, in order to maintenance a high input impedance. And

the low range’s range is ±2.2V.

For the RNG_H, the input

impedance is 10M, RNG10’s gain is ~1/5, RNG20’s gain is ~1/10, and RNG50’s gain

is ~0.43/10. The range switching is done by a low leakage 4:1 analog switch.

The input voltage id

buffered by AD8628, it’s a RRIO amplifier, with a typical 50pA offset current,

and 0.5uVpp low frequency noise. What’s more, it’s available in JCL SMT library.

U3 is a low cost dual

RRIO amplifier, one channel is used to buffer the 2.5V from the reference IC,

used as system common mode voltage (VCM). And another channel is working as an

adder, add 1.25V reference and 2.5V VCM together used for self-calibration.

U2’s part B can route

the DVM+ to VCM or 1.25V Vref for system offset/gain calibration for each

range. The connector “CAL” is used for outside calibration.

The voltage divider’s

absolute accuracy is not so important, theoretically the ratio can be

calculated during calibration.

Notice: there is a

fatal error in the high range voltage divider. I will descript it in Part B.

2.1 VFD driver

circuit

The VFD (SAMSUNG

HCS-12SS59T) need a relative high voltage (Vdis=33V) to provide electric field

for electron acceleration, here using the low cost MC34063 to build a boost circuit.

Q1 used as power supply switch, since the datasheet request the display voltage

must turn on after the filament voltage is given and turn off before the filament

voltage is off. R26, C25, C26 are the RC oscillator for the VFD. It needs a

39pf capacitor but in the LC SMT library this value is not available, so use 2 available

values in parallel here.

The VFD connect to the

MCU via SPI interface.

3. MCU circuit

The system using

STM32f103C8t6 blue-pill board as controller. It gives the chance that user can

use the Arduino to control this system as they want.

On the board it offers

a USB to TTL convertor, connect to the USART port of STM32 blue pill board. And

a CAN transceiver is also reserved, maybe I can use it to connect with many

boards in parallel, then making an average of the measuring result in order to

reduce the noise.

R35&R36 used as a voltage divider, connect to the blue pill’s ADC channel, to monitoring the system voltage, and control the display's voltage.

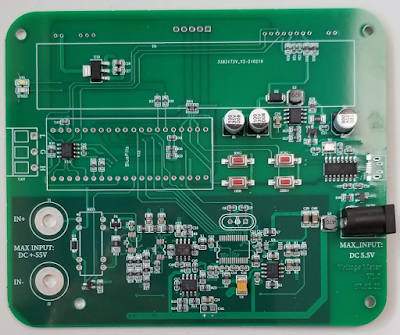

The PCB is 120mm*100mm,

with 4 layers.

You can find the schematic here:

https://drive.google.com/file/d/1PfmhBDpNsJP1FyqyJ5L2pe54IcSiVEGW/view?usp=sharing

and Gerber file here:

https://drive.google.com/file/d/1KaQ4vSXYg2az2gumgiCddYIEk65w-MtM/view?usp=sharing

In the next article I

will introduce the debugging and HW bug fix, as you may notice there are many modifications

in the real PCB board.

评论

发表评论